HEPROP™ Technology

02

- 02

- HEPROPTM

- Technology

- Contents

- 5

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- Modified fiber

- Structural stabilizer

- What is HEPROPTM?

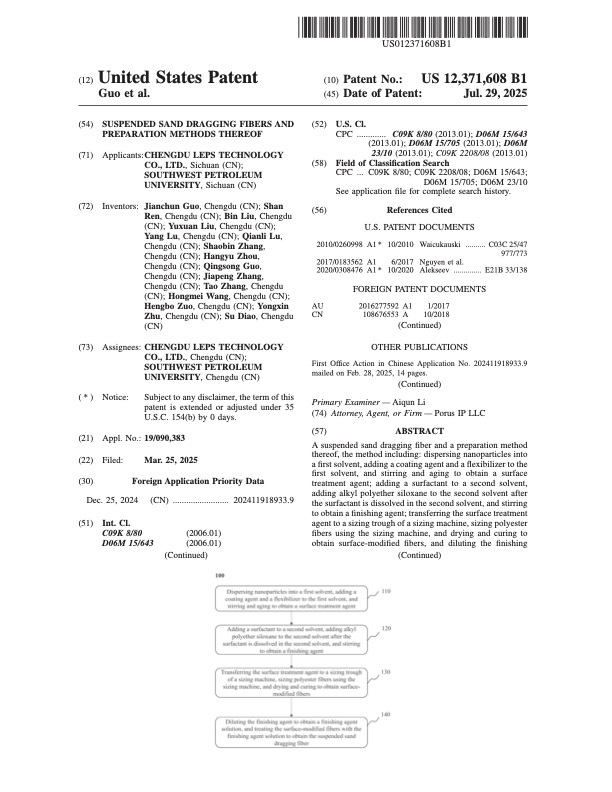

- US patent

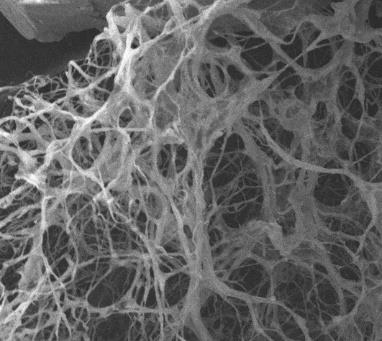

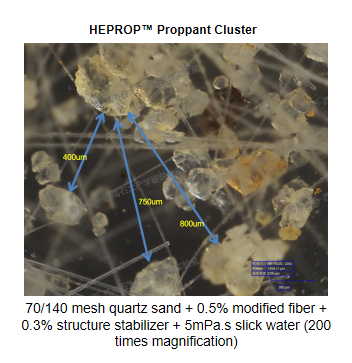

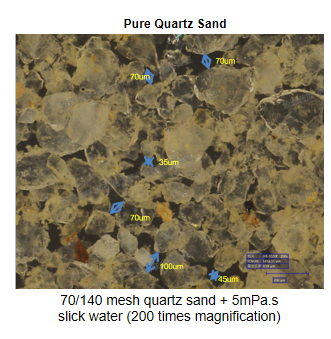

- HEP fiber, combined with the structural stabilizer, forms a lattice porous network much like a “spiderweb.”

- Proppant

- Slick water

- 6

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- HEP can increase the proppant spacing 6-10 times than traditional technology.

- Core Mechanism

- What is HEPROPTM?

- 7

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- Significantly reduces flow pressure difference and enhances artificial fracture permeability. At 2,175.6 psi closure pressure and the same displacement rate, HEP cuts flow pressure by over 90% and boosts permeability by 6–10 times compared to pure sand.

- Outlet

- Placement Status Inside the Fracture

- Comparison of Flowing Pressure Difference and Permeability

- 8

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- Carrying Distance: 0.5% modified fiber + 0.3% structure stabilizer increases effective fracture length by 30%.

- Stacking Height: 0.5% modified fiber + 0.3% stabilizer increases placement height by 100%;

- Increase the proppant carry distance by 30%

- Device : fracture width 0.2in * length 9.84ft * height 1.3ftm

- Experimental conditions: 70-140 mesh quartz sand, 10% sand ratio, 5mPa.s slickwater

- Pure sand

- HEP: 0.5% modified fiber + 0.3% stabilizer

- Increases placement height 100%

- 9

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

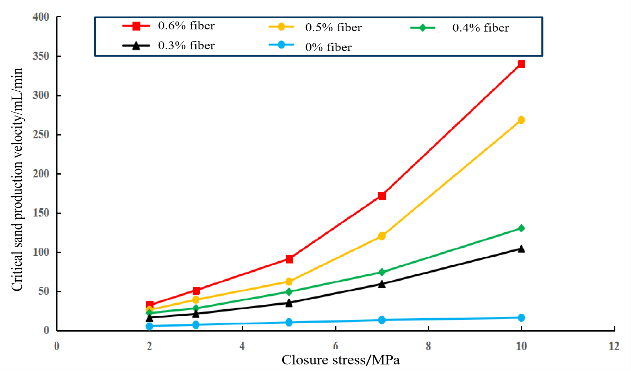

- Structured support has better geometric stability, maintaining the stability and integrity of the sand pack, and improving long-term production stability. Increase the critical sand production flow rate.

- Plate Dynamic Simulation — Comparison of Different Processes, Backward Displacement, and Proppant Placement Patterns

- Comparison of Critical Sand Production Flow Rates with Different Fiber Additions in 70-140 Quartz Sand

- 10

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- With HEP viscosity of 9-12 mPa·s can achieve full suspension transport of proppant, and the placement height is 4 times than the liquid with viscosity of 24 mPa·s traditional fractrue.

- Reduce friction reducer usage volume and formation damage;

- HEP: 11.7 mPa·s + 70-140 Mesh Quartz Sand 15% + 0.5% Modified fiber+ 0.3% Stabilizer

- Loosening proppant in 60 minutes after pump shutdown

- 11

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- Equipment & Operation Procedure

- Integrated Injection Skip

- The modified fiber and structural stabilizer are mixed and well-dispersed through an integrated injection skid.

- The mixture is then transferred to the blender truck’s mixing tank combined with the proppant and injecte to the wellbore.

- 12

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- Equipment & Operation Procedure

- Integrated Injection Skip

- Without altering the original fracturing injection process.

- 13

Leading Technology for Unconventional Oil and Gas Stimulation

- Leading Technology for Unconventional Oil and Gas Stimulation

- High-efficiency propping technical materials

- Modified fracturing emulsion fluid

- Fracturing design for single well

- Fracturing skid-mounted equipment

- On-site construction technical guidance

- Other required chemicals

- What we can offer

- HEPROPTM

- 24

LEPS

- LEPS

- FOR STIMULATION OF OIL AND GAS

- 25